| Availability: | |

|---|---|

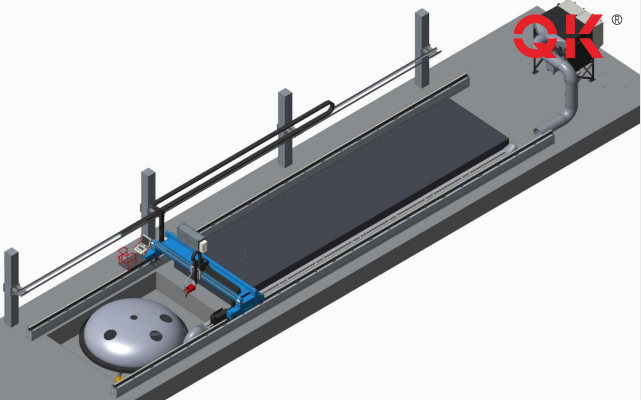

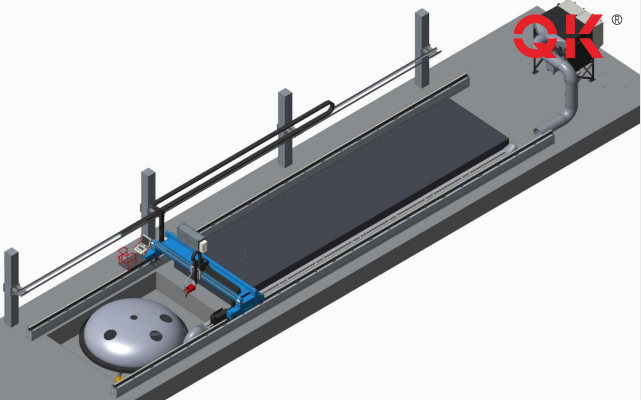

Rack reasonable structure, rigid and durable. Standard brands linear guide, to ensure that lateral movement accuracy and durability;

Stable QHC towers lifting device and double lift guide;

Customer may be connected to the MES manufacturing execution management system;

For customers to choose a variety of configurations, adaptable, we can provide customers with total solutions;

You can solve all the main plane of the steel sheet cutting process and additional processes, such as plasma cutting, flame cutting, straight cutting, scribing dusting, 3D beveling, inkjet marking, plasma dust control;

Machine comes standard with air-way speed of 16 m / min, the customer can choose to increase the speed and acceleration of up to 100mg of cutting corners to meet the needs and holes cut;

Optional automatic cleaning and lubricating the guide rail;

Optional beam forced air heat and prevent thermal deformation of the frame;

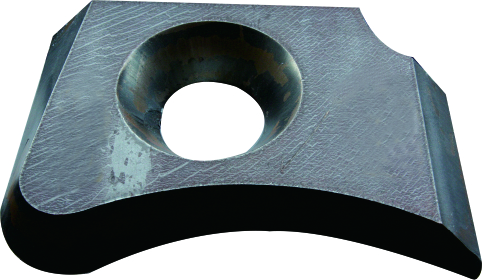

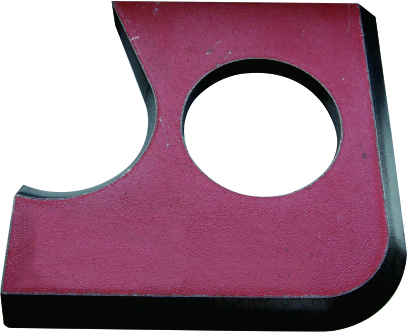

Standard cross protection against splashes of slag, to extend life of the machine.

Rack reasonable structure, rigid and durable. Standard brands linear guide, to ensure that lateral movement accuracy and durability;

Stable QHC towers lifting device and double lift guide;

Customer may be connected to the MES manufacturing execution management system;

For customers to choose a variety of configurations, adaptable, we can provide customers with total solutions;

You can solve all the main plane of the steel sheet cutting process and additional processes, such as plasma cutting, flame cutting, straight cutting, scribing dusting, 3D beveling, inkjet marking, plasma dust control;

Machine comes standard with air-way speed of 16 m / min, the customer can choose to increase the speed and acceleration of up to 100mg of cutting corners to meet the needs and holes cut;

Optional automatic cleaning and lubricating the guide rail;

Optional beam forced air heat and prevent thermal deformation of the frame;

Standard cross protection against splashes of slag, to extend life of the machine.

Machine lateral rail distance / mm: 2500-8000 (interval every 500mm);

Operations Console: Q-Panel Industrial grade 17-inch LCD touch screen display;

CNC system: Optional QKNC + universe Patent bus control system;

Plasma: Plasma can configure multiple sets torch and the lifting device, all models can be configured to fine air plasma and plasma gun library can be configured;

Flame torch: multiple sets of configurable lifting device and the flame torch, cutting torch flame optional inlet, optional straight cutting torch, the flame perforation system three optional flame QK-APC Automatic pneumatic control system;

3D groove means: a plasma flame can be configured with 3D and groove means and lifting means Q350Pro;

Electrical control cabinet: independent electrical control integrated circuit board, IP52 level;

Drive servo system: first-line brand AC servo drive system;

Reducer: First-line brand precision planet reducer;

Protection device: three-color lights, the operation site, travel limit, the power switch, emergency stop switch.

Machine lateral rail distance / mm: 2500-8000 (interval every 500mm);

Operations Console: Q-Panel Industrial grade 17-inch LCD touch screen display;

CNC system: Optional QKNC + universe Patent bus control system;

Plasma: Plasma can configure multiple sets torch and the lifting device, all models can be configured to fine air plasma and plasma gun library can be configured;

Flame torch: multiple sets of configurable lifting device and the flame torch, cutting torch flame optional inlet, optional straight cutting torch, the flame perforation system three optional flame QK-APC Automatic pneumatic control system;

3D groove means: a plasma flame can be configured with 3D and groove means and lifting means Q350Pro;

Electrical control cabinet: independent electrical control integrated circuit board, IP52 level;

Drive servo system: first-line brand AC servo drive system;

Reducer: First-line brand precision planet reducer;

Protection device: three-color lights, the operation site, travel limit, the power switch, emergency stop switch.

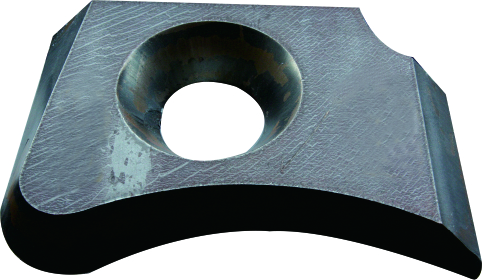

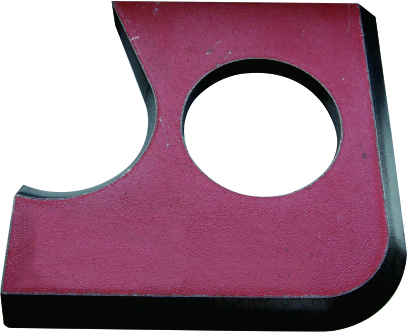

Dust removal workbench and water bed workbench/industrial smoke and dust purifier/main unit power supply regulator/plasma air assembly/cutting slag automatic cleaning system.

Dust removal workbench and water bed workbench/industrial smoke and dust purifier/main unit power supply regulator/plasma air assembly/cutting slag automatic cleaning system.

Kunshan Qiankun Machinery Manufacturing Co., Ltd.

After more than ten years of continuous efforts, we have delivered more than one thousand sets of various cutting machines, which create value for customers all over the world. Every year, nearly half of the machines are exported to Southeast Asia and Europe.

SOCIAL ATTENTION

Copyright © 2021

Kunshan Qiankun Machinery Manufacturing Co., Ltd.

Partners:Leading foreign trade station

record number:Su ICP No. 2021003781